this post was submitted on 12 Mar 2024

991 points (97.8% liked)

memes

10283 readers

3137 users here now

Community rules

1. Be civil

No trolling, bigotry or other insulting / annoying behaviour

2. No politics

This is non-politics community. For political memes please go to [email protected]

3. No recent reposts

Check for reposts when posting a meme, you can only repost after 1 month

4. No bots

No bots without the express approval of the mods or the admins

5. No Spam/Ads

No advertisements or spam. This is an instance rule and the only way to live.

Sister communities

- [email protected] : Star Trek memes, chat and shitposts

- [email protected] : Lemmy Shitposts, anything and everything goes.

- [email protected] : Linux themed memes

- [email protected] : for those who love comic stories.

founded 1 year ago

MODERATORS

you are viewing a single comment's thread

view the rest of the comments

view the rest of the comments

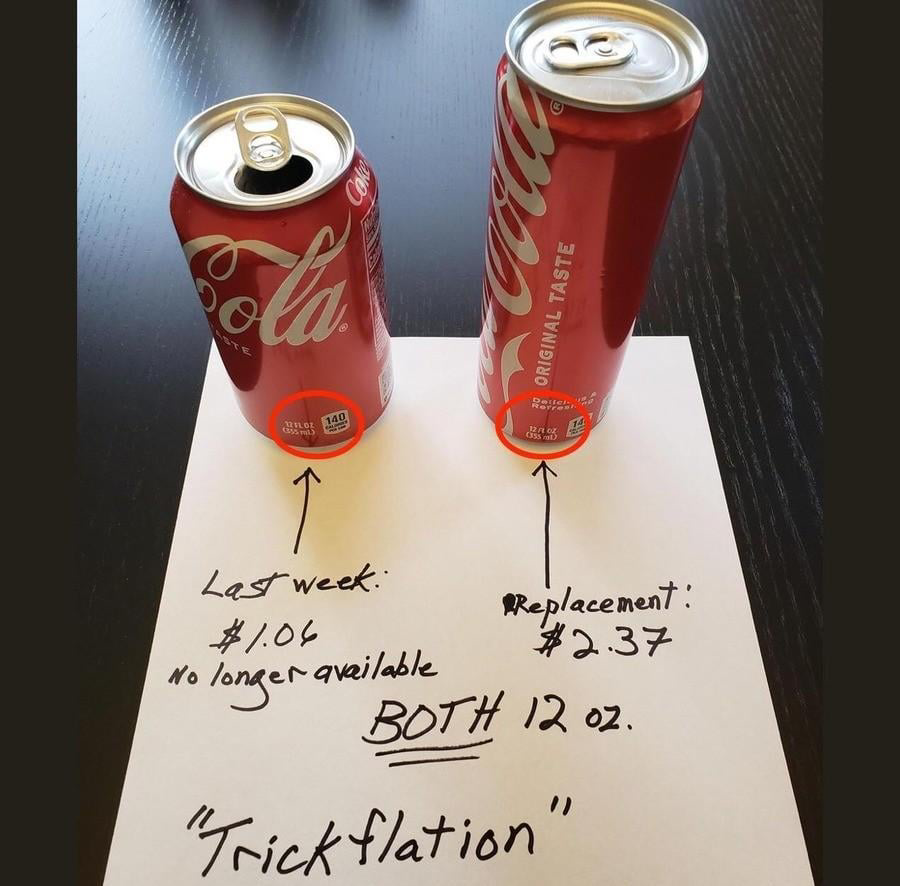

I always thought that narrower pressure vessels could contain higher pressure, because the curvature is more severe, meaning that for a vessel that needs to retain a similar level of pressure, you could just use less material in the walls of the vessel. Is this not the case with these new cans, and they have the same wall thickness, or is the tradeoff just one that still works out to be in favor of more total aluminum usage?

Force inside a cylinder vessel is just pressure times surface area. If you have the same pressure(soda carbonation) with more surface area, then you are putting less force on the walls. I don't have any specialty in the materials engineering for canning, but i suppose less force on the walls means you could use thinner materials. However, soda can walls are already pretty thin to start with and from what I can find online, the tops are usually 2.5-3 times thicker. So, I could see it potentially cutting some cost from the tops by making them thinner but i doubt they are manufacturing different tops. It's probably just marketing.