As others have said they look like jst but I always get the sizes wrong so I just stock all of them. You need the metal crimp bits and the white housing, as well as a crimper.

You strip like 2mm of the wire sheathing and crimp the short blades over the bare wire and the long ones over the sheathing which gets punctured. The crimper curls the blades towards the center when aligned well. For the really tiny ones you need the crimper with the doubled up die that crimps both sets of blades at the same time. The bigger ones you might be able crimp each side separately if the tool fits. With the tool that does it in one go I use my fingernails or tweezers to place the crimp end in the die/jaws of the crimper, click the minimum number of times for it to stay while not bending it too much, then put the stripped wire in really carefully without bending the strands before squeezing the remaining clicks in the crimper. I've also seen people bend the bigger blades by hand to make it stay on the wire then put the whole thing in the tool but I can't do it that way myself.

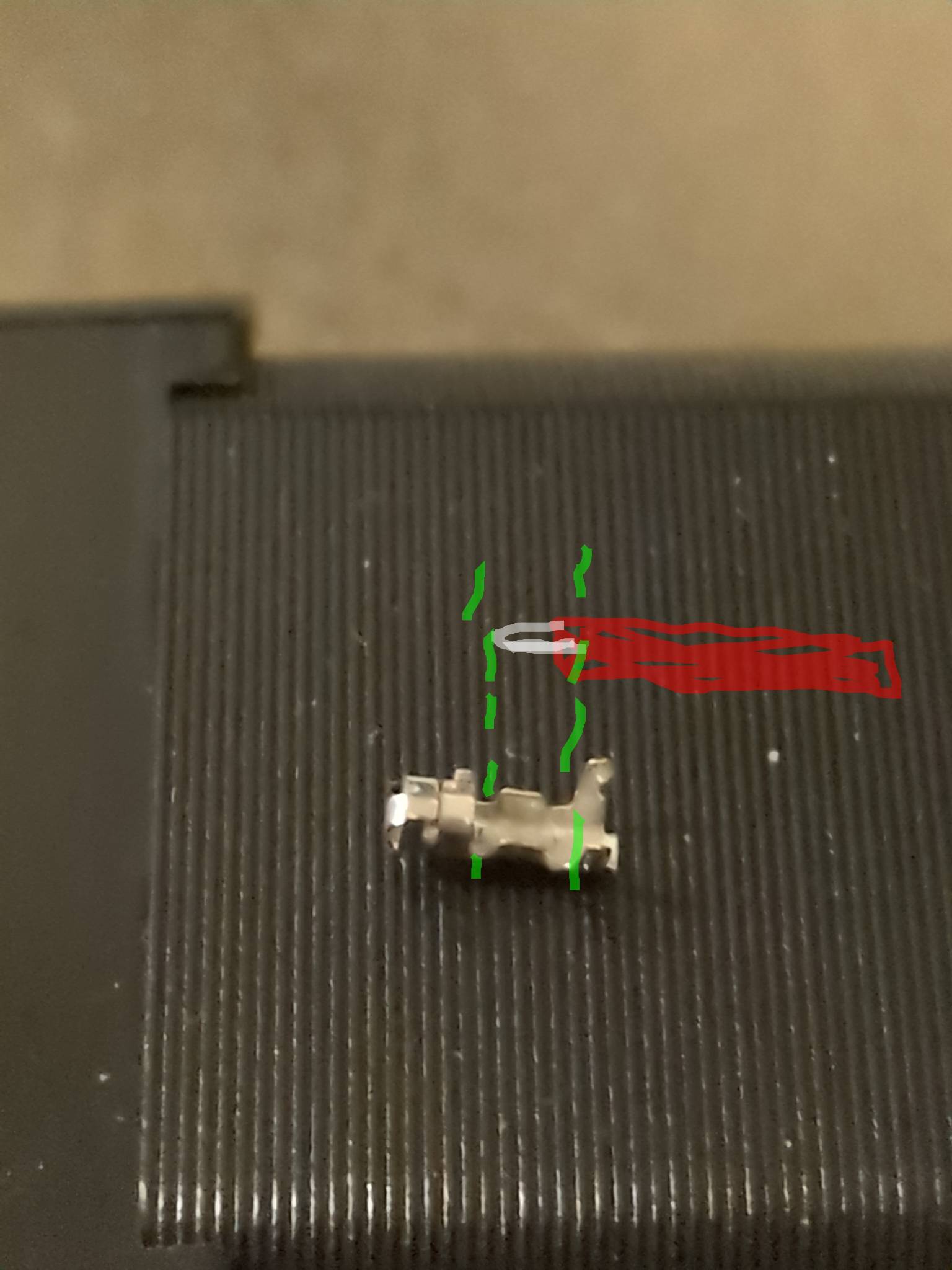

I moved most of my tools to my new place ahead of the actual move in date and the piece in the pic is just found on the floor or I would have sent better examples of the tools and some failed and successful crimps. I recommend the kit and anticipating a few wasted metal pieces because they are tiny and fumbly and the tool feels ridiculously huge.