3DPrinting

3DPrinting is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

The r/functionalprint community is now located at: or [email protected]

There are CAD communities available at: [email protected] or [email protected]

Rules

-

No bigotry - including racism, sexism, ableism, homophobia, transphobia, or xenophobia. Code of Conduct.

-

Be respectful, especially when disagreeing. Everyone should feel welcome here.

-

No porn (NSFW prints are acceptable but must be marked NSFW)

-

No Ads / Spamming / Guerrilla Marketing

-

Do not create links to reddit

-

If you see an issue please flag it

-

No guns

-

No injury gore posts

If you need an easy way to host pictures, https://catbox.moe/ may be an option. Be ethical about what you post and donate if you are able or use this a lot. It is just an individual hosting content, not a company. The image embedding syntax for Lemmy is

Moderation policy: Light, mostly invisible

view the rest of the comments

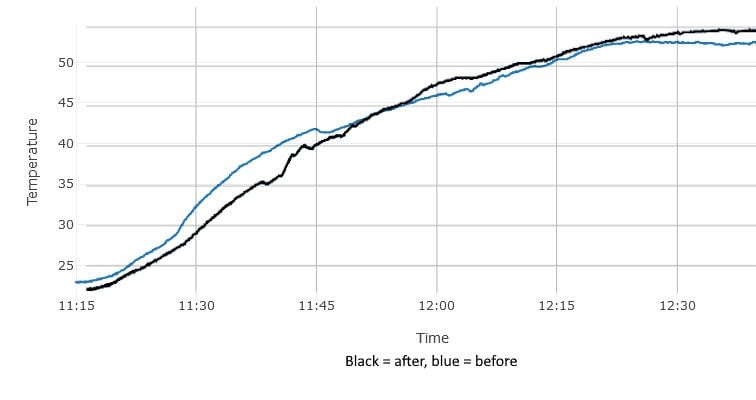

Somewhat? The printer is in my basement, which we don't actively heat. It's 60 °F / 25.5 °C down there.

The door gives you a much better seal, but it also gives you a thicker panel that will help insulation some. I saved one my acrylic side panels and will be attaching it to the door too to make a double pane... thing.

Glad I'm not the only one, lol. I am kind of considering adding more bedfans to maybe help.

I spaced out my ACM panels about 1/2" wider than stock to accomodate the radiant barrier inside the frame while still giving the gantry space to move. I'm somewhat on the fence about how permanent I want the insulation to be. Kapton tape around the edges is removable and might just pass the "good enough" threshold, even though it will prevent me from going completely edge to edge.

This sounds pretty complicated. I think you could accomplish similar with a traditional double pane setup. The Linneo Nanonest is a double pane panel you can use in cllicky-clacky, but it was out of stock when I ordered my parts.

I spent a tiny amount of time looking at r-values for the various panels and they're all not that high TBH. If you don't mind the look, an external layer of foam insulation is going to be by far the best bang for your buck.

I'll follow up with radiant insulation in a week or two.

Wow, my house is colder than that WITH heating

We have a 4 and 7 year old and keep the first floor between 63-67 °F. I also realized the Celsius temp above has a typo, it should be 15.5 °C and not 25.5. That would indeed be warm, lol.

Oh ok that makes more sense !